1.CNG Compressor/Natural Gas Compressor/Fueling Station Compressor/CNG gas fueling station

2.CNG gas fueling station,CNG is a transportation fuel made by compressing natural gas or biogas to less than 1% of its volume. Natural gas pipelines transport natural gas to CNG stations where it passes through a gas dryer and is compressed through two to five stages of compression until it reaches a pressure of up to 4,500 psig.

Once compressed, CNG is stored and distributed at a significantly lower cost than gasoline or diesel. The compressed natural gas reaches a priority panel that directs into the on-site, above-ground storage vessels. Customers fill their vehicles from the dispenser, much like a conventional fueling station.

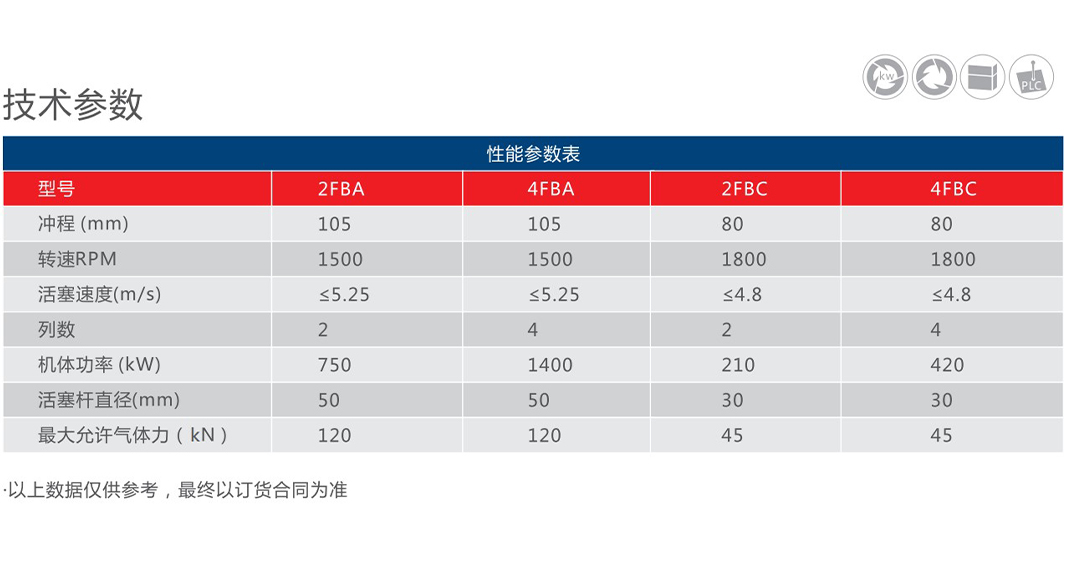

3.Power range: 75~420kW

Maximum discharge pressure: 25MPa

Maximum speed: 1500r/min

The maximum displacement is: 10 × 104 Nm3/d

Description:

The CNG compressor is a series of products specifically developed for CNG vehicle refueling stations. The units utilize a reciprocating piston structure and modular design. By combining variations in the unit body and cylinders, multiple models can be derived, covering a wide range of intake pressures (0.1~20 MPa) and gas supply capacities from 300 Nm³/h to 6000 Nm³/h.

All series of CNG compressor units are fully assembled and tested at the manufacturing facility, presenting complete sets that are compact, highly integrated, and equipped with aesthetically pleasing dedicated soundproof enclosures. They can be installed outdoors, featuring a small footprint, simple foundation requirements, easy installation, cost-effectiveness, and quick commissioning.

Cooling options include air-cooling, water-cooling, and hybrid cooling, catering to various types of CNG vehicle refueling stations, conventional stations, mother stations, and substations.

Applications:

CNG compressors play a crucial role in various applications where compressed natural gas (CNG) is used as a fuel or needs to be transported efficiently. Here are some common applications:

1. **CNG Vehicle Refueling Stations:**

- CNG compressors are extensively used at CNG refueling stations to compress natural gas before it is dispensed into vehicles. These stations can be located along highways, in urban areas, or at commercial facilities.

2. **Public Transportation:**

- Many public transportation fleets, such as buses and taxis, use CNG as a fuel source. CNG compressors are employed to provide a reliable and continuous supply of compressed natural gas for these vehicles.

3. **Industrial Applications:**

- Industries may use CNG as a clean and cost-effective fuel for various processes. CNG compressors are used in industrial settings where a compressed natural gas supply is required for manufacturing or power generation.

4. **Commercial Fleets:**

- Some companies operate fleets of CNG-powered vehicles for their transportation needs. CNG compressors enable the efficient refueling of these commercial vehicle fleets, reducing dependence on traditional fuels.

5. **Utilities and Power Generation:**

- CNG can be used as a fuel for power generation in certain situations. CNG compressors are employed to ensure a steady and pressurized supply of natural gas for power plants.

6. **Residential and Commercial Heating:**

- In some regions, CNG is used for residential and commercial heating applications. CNG compressors may be used to provide a compressed gas supply for these heating systems.

7. **Gas Pipeline Maintenance:**

- CNG can be transported through pipelines for distribution. CNG compressors play a role in maintaining the pressure within these pipelines to ensure the efficient and safe transport of natural gas.

8. **Backup Power Systems:**

- CNG can be used as a backup fuel for power generation during emergencies. CNG compressors may be utilized to maintain a pressurized storage of natural gas for these backup power systems.

9. **Mobile CNG Stations:**

- In areas without fixed CNG infrastructure, mobile CNG stations equipped with compressors can be deployed temporarily to provide a convenient refueling option.

CNG compressors contribute to the wider adoption of natural gas as a cleaner and more environmentally friendly alternative to traditional fuels in various sectors.

Competitive Advantage:

The design features a low specific bearing pressure for transmission components, ensuring high reliability and an extended lifespan for vulnerable parts.

The cylinders are lubricated with minimal oil, and each stage is equipped with efficient oil filtration.

The pneumatic system maintains low flow velocity, incorporating exhaust buffer tanks at each stage to reduce airflow pulsation, promoting energy efficiency.

The unit is fully assembled, compact, and aesthetically pleasing, facilitating easy installation.

Utilizing a dedicated soundproof enclosure, the unit exhibits low noise levels.

Equipped with a visual and intelligent control system, the unit is user-friendly, ensuring safety and reliability.

Tag:

CNG Compression

Natural Gas Vehicles

Alternative Fuels

Energy Infrastructure

Transportation

Environmental Solutions

Compressor Technology

Renewable Energy

Gas Station Equipment

Industrial Applications

Description:

The FB series compressor is a fully balanced, reciprocating plug type variable operating condition compressor, with advantages such as high speed, compact structure, economical use, easy operation, and convenient maintenance. The driving method is flexible, and diesel engines, electric motors, and natural gas engines can be selected according to needs. This series of compressors can be widely used in light hydrocarbon recovery, turbocharging, gas transmission in oil and gas fields, as well as in standard stations, sub stations, and mother stations of CNG automotive refueling stations.

Main specification:

Intake temperature: ambient temperature

Inlet pressure range: 0.1~20MPa (G)

Exhaust temperature:Displacement: 300-5000Nm/h

Feature:

High Rotational Speed

Featuring a fully symmetrical and balanced design, this eliminates imbalances in the torque during crankshaft operation.

Standardized, serialized, and modular in design, the unit offers flexibility in configuration and is technologically reliable.

Utilizing air-cooled cylinders eliminates the need for cooling pipelines.

Tailored to various design requirements, it can provide short, compact single-chamber (Type I) and long single-chamber (Type) intermediates commonly used in oil fields.

Cylinders can be used as double-acting or single-acting (differential type) cylinders, allowing for flexible design combinations.

Cylinders incorporate larger intake and exhaust valve chambers, minimizing airflow pulsation at the intake and exhaust ports.

All column packing is fully interchangeable, reducing the number of spare parts, and the packing seal pressure differential reaches up to 25 MPa.

The main engine's moving parts are lubricated with bidirectional oil injection, with a top-mounted oil inlet for the main oil circuit. This ensures reliable lubrication, a more rational oil channel structure, and easy cleaning of the oil circuit.

The main shaft features a top-mounted oil inlet and is equipped with main bearing temperature detection.