Bop subsea is important in deepwater drilling operations for the energy sector. Its systems are combined to aid in the safety and also productivity in bringing oil and gas commodities from below its depths. This article will reveal the recent advancement in Xiangjing Blowout Preventer(BOP) subsea technology, its advantages, innovation and application.

The Recent Developments In The Field Of BOP Subsea

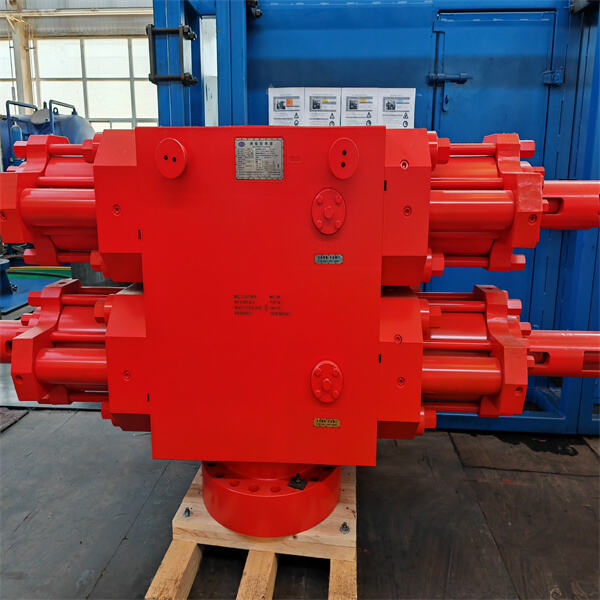

The BOP subsea is an important device resting beneath thousands of feet of water on the seafloor. It is often sited at off-shore drilling grounds. It is most commonly used when drilling in unruly and woody place without any protection from oil and gas that might surge from there at uncontrollable pressure.

This new equipment combines the functionality of a conventional stack-style blowout preventer with other drilling tools which cuts down drill time and speeds up the activity. The safe handling of these technologies is key to increasing security, while avoiding oil pollution in the process adding even more environmental protection.

Remote monitoring: A highlight in the bop subsea systems brought by players One of the advantages is it allows for real time remote gear monitoring so you can catch problems early and potentially save yourself a big repair bill down the road.

When bop subsea systems need to be in service and most important are attention to detail right down to almost infinite degree, combined with meticulous care. A common myth is that this technology can be bypassed if time disallows and Xiangjing Blowout Preventer(BOP) subsea will work without it so we do not have oil or gas flow uncontrolled.

Safety in such operations is critical as deepwater drilling comes with inherent risks. To mitigate risks of accidents and oil spills with workers associated with deep water drilling operations closure technology made possible in the development related to Xiangjing Blowout Preventer(BOP) subsea. A defect within the piece of equipment might lead to an unrestrained discharge from well endangering lives, along with a risk to environment as shown above. This is why when safety crashes, our marine life and ecosystems burn but also local livelihood injuries.

As it is well known this type of system operates in extreme depths and under tough circumstances, regular maintenance must be done to keep the bop subsea equipment functioning.

This is a same kind of program like that one for the computerized equipment preventive maintenance initiative. Weekly walk-through and taking preventative measures by having that aura to anticipate errors even before they come, assuring the Blowout Preventer(BOP) are always in its best condition while avoiding surreal breakdowns.

The most punctual model of bop subsea systems happened and almost ended up what divergent sector which took decades to adopt. It is believed that modern drilling operations will still protect the significance of Blowout Preventer(BOP) subsea because not only energy requirement increase, but also strengthen down hole pressure in order to environmental protection. These systems are only reliable and usable if you have kept them in good working condition through routine maintenance, along with the regular detailed inspection.

Our team of over 500 professionals will Bop subsea throughout the entire process. From pre-sales to after-sales support our professionals deliver expert assistance throughout the entire process. We welcome customers from China meet on site and maintain open communication channels to foster long-lasting partnerships.

We've Bop subsea, and we serve customers from all over the world. We are able to provide localized services throughout the world as our team is well knowledge of the various regional markets. We're specialists in meeting the needs of each customer and solving difficult problems across different markets.

Our gasoline and oil equipment comes from the top Chinese manufacturers, which is the Bop subsea and innovation. Supported by extensive R and D and production expertise, each product is meticulously made to meet or exceed customer expectations and set new standards in the industry.

Every need for automation in your industry are met by us. With more than a decade's expertise we Bop subsea, distribute, and sell our own products while also representing top international brands. Our wide ranges of products spans many industries and provides a customized solutions to each customer.