Which Safety Equipment Is Best for an Oil Rig

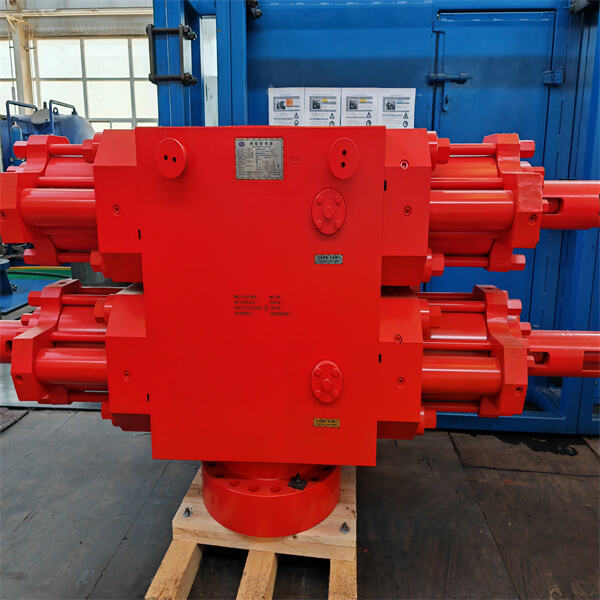

There is plenty of risk associated with working on oil rigs. Accidents can happen unprepaired and the consequences may be severe enough. That is why it falls on you to properly kit out, and that means having the correct safety equipment, like blow off preventers (BOPs). The tools are developed to rapidly close down operations when there is an emergency, avoiding oil and gas from dripping out.

In the selection of an appropriate BOP for your oil rig, there are several key points to keep in mind. The pressure rating, fit and compatibility with the other equipment within your kitchen are considered during this evaluation. You also want to confirm that your BOP is made following standards as the API (America Petroleum Institution).

The main importance of blow off preventers is to stop catastrophes that can occur in the oil & gas industry. Should an emergency happen, they are capable of sealing off wells in mere moments and assure spills or explosions averted. TYPES OF BOPs Blow-out preventers come in numerous types, each performing a different function to support the protection of oil and gas wells during emergency situations.

You want to be sure that when the time arrives, your BOP system functions as it should and this means keeping on top of its maintenance. Distance Inspections and frequent testing Checking the seals, hydraulic system and electrical connections thoroughly is crucial.

Reaping the Benefits of Technological Progress for Safety

The world of BOP systems is expanding with new incorporations, that include the latest technologies. New models are more reliable and feature safety improvements that reduce their operation cost. Technological advancements such as sensors allow operators to receive real-time data on wells and can trigger the BOP automatically if necessary.

Blow off preventers form a bedrock in worker safety and environmental protection. They prevent calamities and can reduce spill environmental dread by hundreds of percents. There are penalties for noncompliance with certain BOP regulations, so using the right type of BOP is critical.

Choosing the right BOP is essential to keep oil rigs safe. If not maintained regularly, this system cannot be operated. While technology has changed, we also must consider safety measures and our efforts in environmental protection.

Any operation is done safely as the topmost priority, and for any responsible company who cares of their workers/environment cannot simply ignore the use of blow

With blow off preventer, we serve customers from all over the world. We can offer localized services all over the world since our team is well understanding of different regional markets. We have a great understanding of the needs of each customer and solving complex problems across different markets.

All your industrial automation requirements can be met by our teams. With more than a decade's experience we have blow off preventer creates and distribute our own products and represents top international brands. Our varied portfolio includes a variety of sectors ensuring tailored solutions for every clients.

Our team of 500+ blow off preventer throughout your entire journey. Our specialists provide expert advice from pre-sales to after-sales. We also offer visits to the site as well as welcome visitors to China and ensure open communication channels creating lasting relationships and accelerating industry expansion.

Our gasoline and oil equipment comes from the top Chinese manufacturers, which is the blow off preventer and innovation. Supported by extensive R and D and production expertise, each product is meticulously made to meet or exceed customer expectations and set new standards in the industry.